Written by Gimmy

01 Mar 2015

“If your father just bought a €200,000 Ferrari, would he let your 15-year-old brother drive it? Chalmers would.”

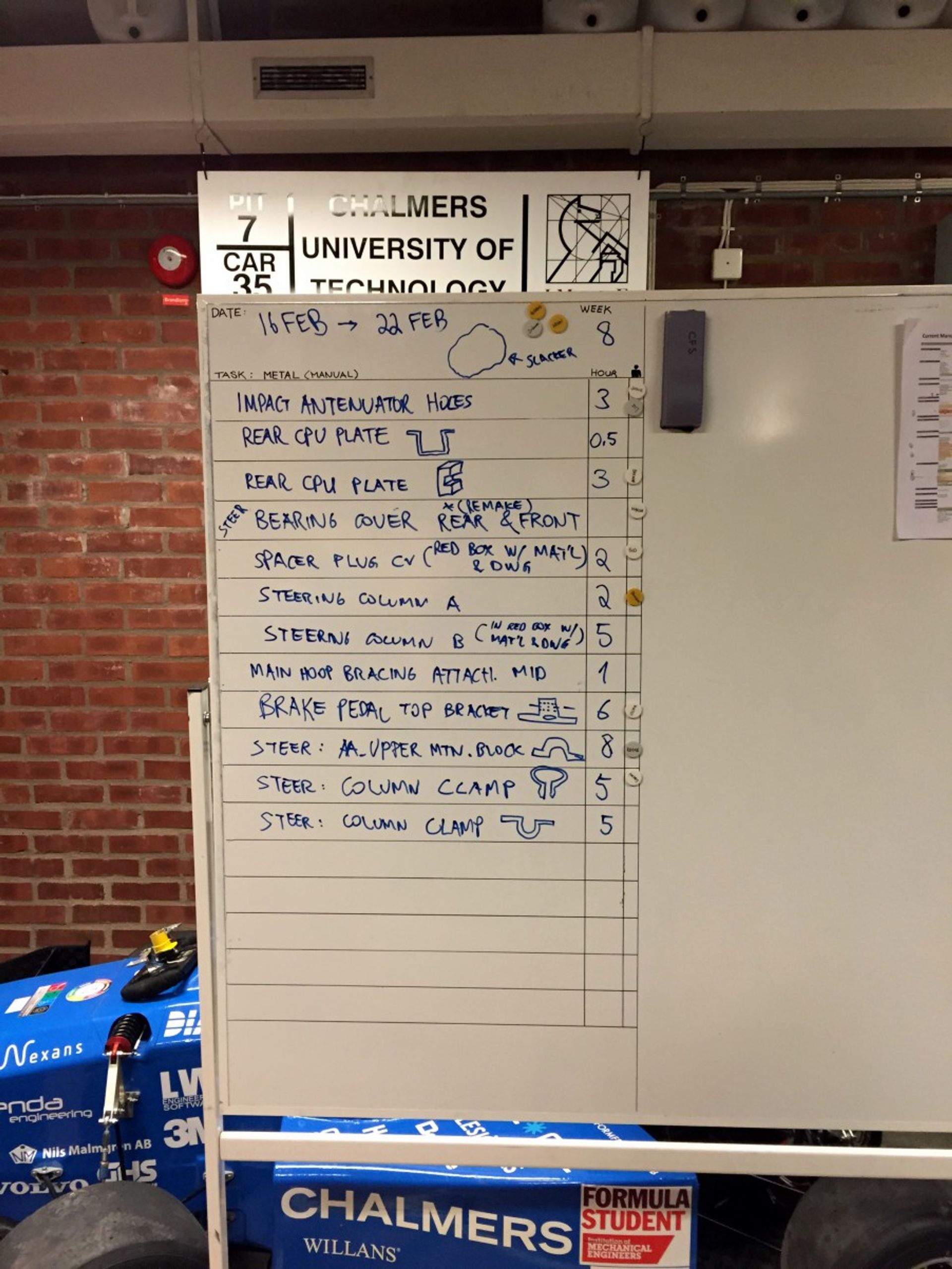

(photo: Josue from Ecuador waiting for auto-feed to complete a pass)

1 March 2015, Gothenburg, Light intermittent Snow, 2 degrees C

After breaking another personal record, 15 hours of continuous sleeping, I feel my mind and senses have been recalibrated again.

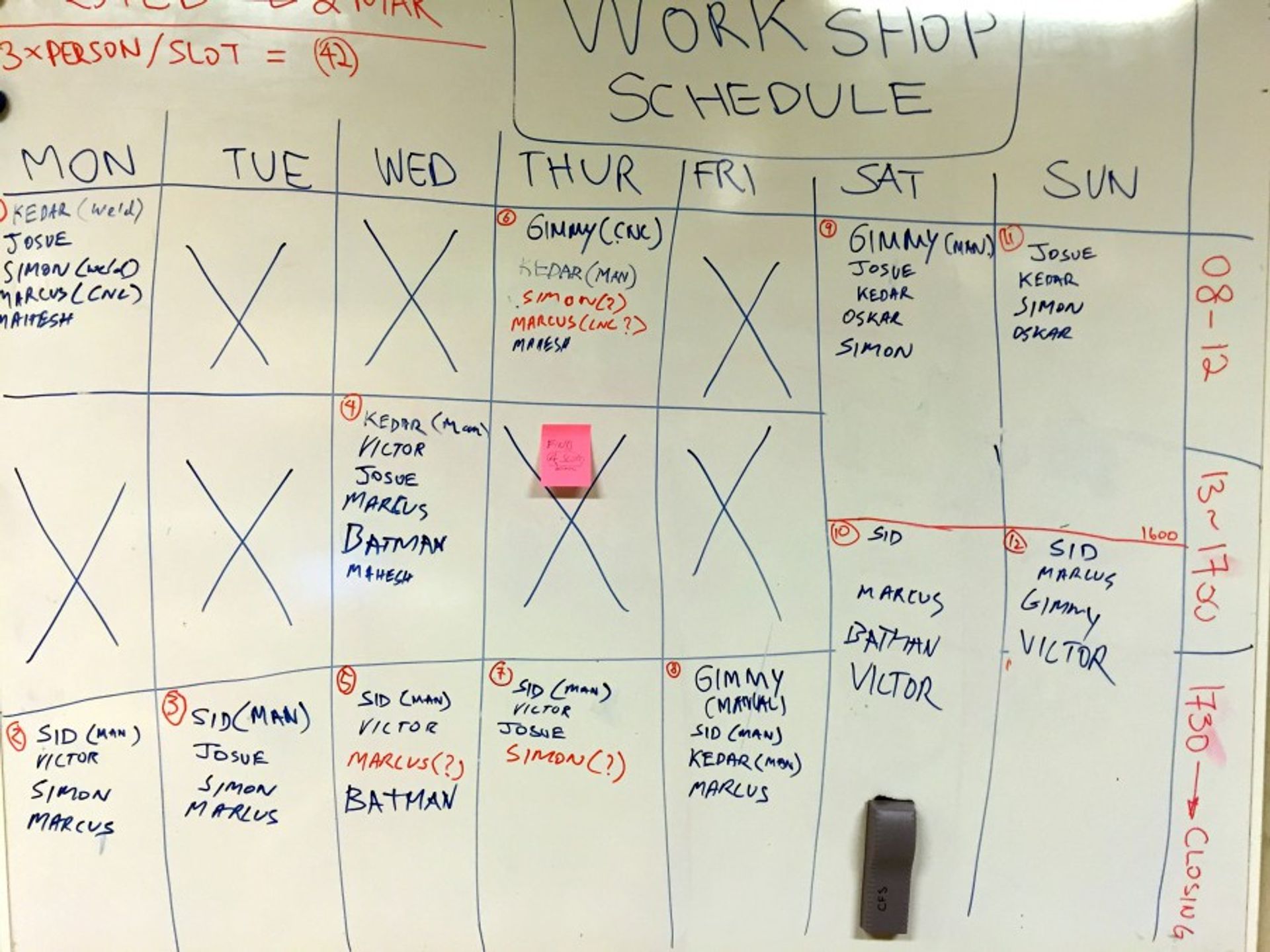

I have been busy at the machine shop lately.

Today I wanted to say a few good words about Chalmers’ machine shop resources and this “CDIO” thing.

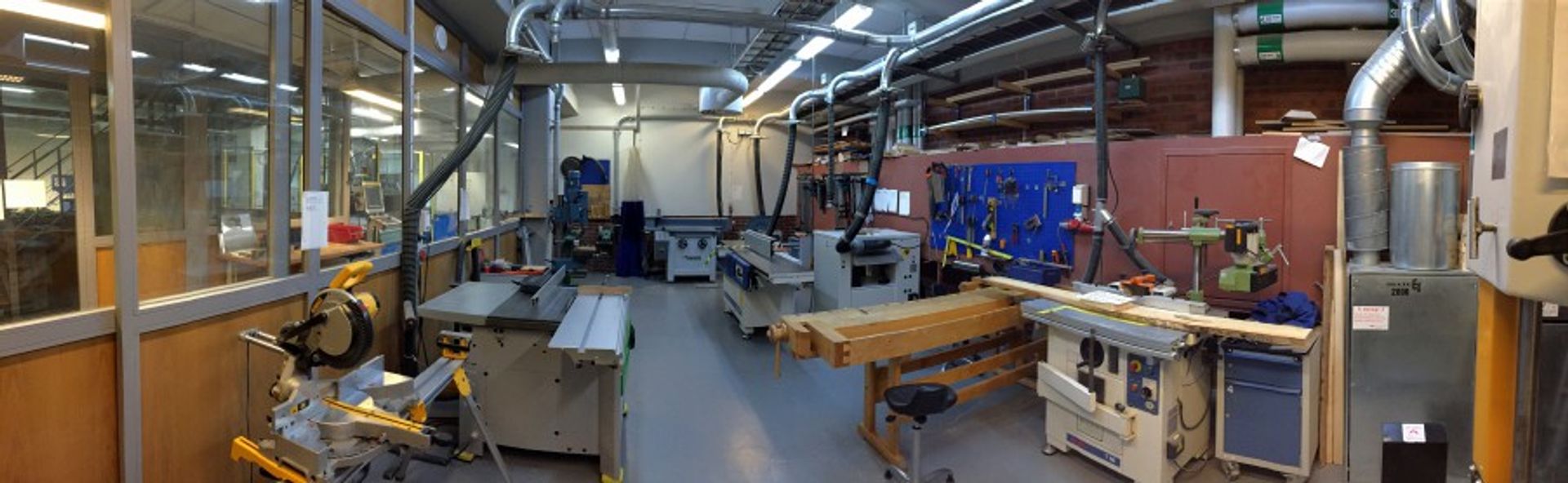

It’s not a massive machine shop… smaller than U of Waterloo shop. But it does the trick!

Chalmers is in the vanguard of CDIO development back in the late 90s and early 2000s. It is spread worldwide now. CDIO stands for Conceive, Design, Implement and Operate. It is an engineering teaching philosophy that is aimed at increasing graduate engineer’s “competency”. (I am not saying engineer graduates are useless, but I have met graduates that don’t know how to use a wrench…).

In short, most engineering schools focus on theoretical part of “Conceive” and “Design”, but overlook “Implement” and “Operate” part. But under CDIO, students must be responsible for the “manufacturing” and “functionally” of their design. (In other words, you earn your marks by designing something and then proving your design physically works).

BUT there is a catch. In order to realize the “Implement” and “Operate” in CDIO philosophy, the school has to provide the necessary manufacturing resources. If you are not familiar with mechanical engineering equipment, they are EXTREMLY expensive (to purchase, to maintain, etc.).

Chalmers wood workshop

Not many schools in the world have such student machine shop resources. While studying at U of Waterloo, I remember a fellow U of Calgary comrade “drooling” over the Waterloo machine shop. Apparently at U of Calgary, they have a few primitive handheld tools. Waterloo has a great workshop, I am very proud of it.

But my concern with the Waterloo machine shop is not all students receive the necessary training.

00 School blindly trust students’ “common sense”

10 Students (often unintentionally) mess up the machines

30 Many “fancier” machines are off-limit to students.

40 The machine shop closes at 9PM and reopens at 8AM. Opening hours are even shorter on weekends.

50 School trust the student less.

60 Go to “00”

Chalmers machine shop is run very differently.

The students have to earn their “driving licenses” by proving their capabilities (both theoretical, but also his or her “maturity and responsibility”). The entire process reminds me of going through driving school. Finally, once you have earned your “credibility”, you can work without supervision after hours (1700-2400).

INSANE! So much trust invested in us!

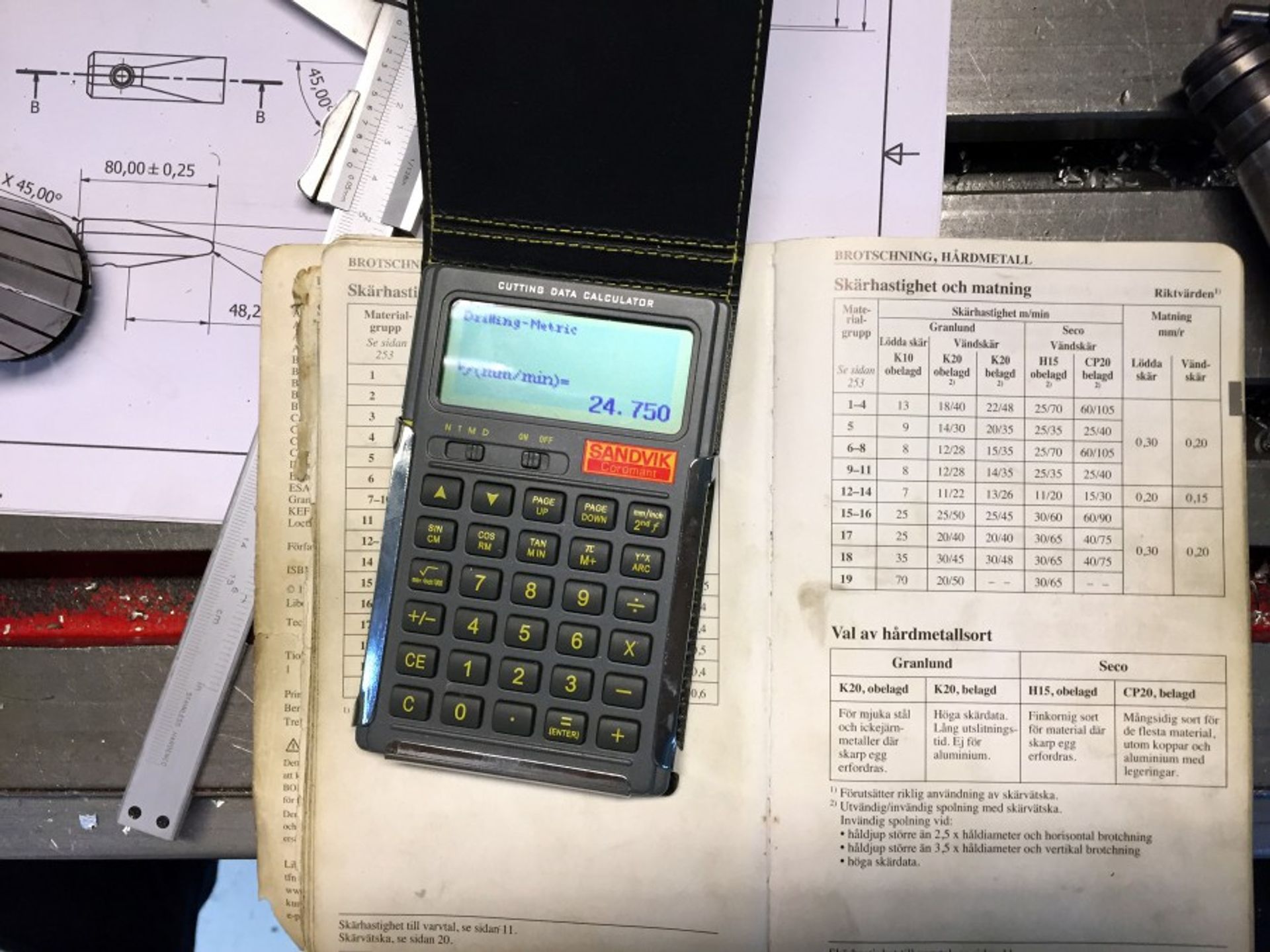

Yes, there is a lot of theory behind machining! Machining isn’t just “muscle” work.

Så, I was playing around with the TIG welding machine in the machine shop the other day. It was quite possibly the happiest moment in January. It is fantastic that the school’s machine shop has two TIG machines (one for aluminium welding and one for steel welding) and a MIG welding machine for students to “play around” with!

Welding room

As I was exclaiming how “trusting” Chalmers is to let me “monkey” around with fancy welders, Johannes slams my praise “oh this is nothing. The school let us play with expensive CNC machines…” (Johannes is our “Design Expert” on the Chalmers Formula Student (CFS) team. He is a very talented guy. I’ll write about him and other gods from CFS next time.)

True. Johannes is right. It’s no big deal. If welding machines are comparable to “brand new BMWs”, then those CNC machines are like “Lamborghinis”.

I’ll write about those CNC machines the next time.

Back to the workshop!

Löv,

gimmygöteborg